饲料供应链中的生物安全 - AASV 2020

来源:猪译馆 2020-04-07 13:48:48| 查看:次

译者的话:<<

本研究的目的是确定为多个猪场供应饲料的饲料厂在猪场爆发病毒性疾病的时候饲料厂是否存在肠杆菌科细菌,并通过这种方法找出是否存在生物安全漏洞。

遵守生物安全规定对肠杆菌科细菌在整个饲料厂的流行和分布有重要的意义。随着各设施开始将生物安全从猪场转移到饲料厂,使用环境监测来评估生物安全漏洞的风险以及成功地缓解这些风险将是非常有用并且必要的。

饲料供应链中的生物安全 - AASV 2020

Applying biosecurity to the feed supply chain - AASV 2020

介绍Introduction<<

作者 Author:

C. Jones1, PhD; S. Stewart1, PhD; J. Woodworth1, PhD; S. Dritz2, DVM, PhD; J. Gebhardt2, DVM, PhD; C. Paulk3, PhD

1堪萨斯州立大学动物科学与工业学院

Department of Animal Sciences and Industry, Kansas State University, Manhattan, Kansas;

2堪萨斯州立大学诊断医学/病理生物学系

Department of Diagnostic Medicine/Pathobiology, Kansas State University, Manhattan, Kansas;

3堪萨斯州立大学粮食学与工业系

Department of Grain Science and Industry, Kansas State University, Manhattan, Kansas

介绍 Introduction

多年来,环境监测一直被广泛应用于食品和其他生产终端消费品的设施中1,2,并且也成为一种广受欢迎的用于确定病原体是否存在的方法(病原体的存在通常说明存在粪便)3。除了生产直接面向消费者的商品的设施外,一些卫生保健系统还利用病毒和细菌的环境监测来确定卫生和生物安全风险,包括已知对抗生素有耐药性的菌株4。现已发现并证明饲料厂中沙门氏菌属和肠杆菌科的存在有相关性5,但关于肠杆菌科的存在如何与病毒病原体的存在有相关性的信息非常少,特别是在农场和饲料厂。随着猪流行性腹泻病毒(PEDV)、塞内卡病毒(SVA)和轮状病毒等疾病对生产体系造成的压力越来越大,在农场环境中对病毒病原体进行环境监测的潜在用途越来越受欢迎。环境拭子已被证明是用于检测饲料生产环境6和猪场设施内的病毒的有效方法。PEDV通过受污染的饲料原料传播的能力、在受污染的饲料在实验条件下使猪发病的能力7,8、以及能支持动物饲料在北美的疾病传播史的流行病学信息,都使得为养猪企业供应饲料的饲料厂的审查越来越严格。本研究的目的是确定为多个猪场供应饲料的饲料厂在猪场爆发病毒性疾病的时候饲料厂是否存在肠杆菌科,并通过这种方法找出是否存在生物安全漏洞。

Environmental monitoring has been commonly used in food and other facilities manufacturing end-consumer products for years,1,2 and has gained traction as a method to determine the presence of pathogens that typically indicate fecal presence (fecal indicators).3 In addition to facilities producing direct-to-consumer goods, some healthcare systems have used environmental monitoring of both virus and bacteria to determine hygiene and biosecurity risk, including bacteria strains known to be resistant to antibiotics.4 A correlation between the presence of Salmonella spp. and Enterobacteriaceae within feed mills has been demonstrated,5 but little information is available on how the presence of Enterobacteriaceae correlates with viral pathogen presence, especially on farms or in feed mills. The potential use of environmental monitoring of viral pathogens within a farm environment has seen an increase in popularity with the growing pressure placed on production systems from diseases like porcine epidemic diarrhea virus (PEDV), Senecavirus A (SVA), and rotavirus. Environmental swabs have been shown to be effective when detecting viruses within feed manufacturing environments6 and with on-farm use for swine operations. The ability for PEDV to be transmitted via contaminated feed ingredients and for contaminated feed to produce animal illness within research settings,7,8 as well as the epidemiological evidence to support a historical animal feed transmission within North America9,10 has brought increased levels of scrutiny on mills supplying feed to swine operations. The purpose of this study was to identify Enterobacteriaceae presence in the feed manufacturing facilities of a multi-farm system experiencing a viral outbreak as a method of identifying biosecurity gaps.

方法 Methods<<

采样方法和采样点

Swabbing method and location

本研究对3个独立的饲料生产设施(饲料厂1-3)进行评估和采样,并在每次拜访期间进行生物安全评估和审计(在ksuswine.org上公布)。每个饲料厂都有各自的生物安全挑战,要么是正常的操作程序,要么是必须在有限的设施内完成的任务。

Three separate feed manufacturing facilities (Sites 1-3) were evaluated and sampled for this study, with a biosecurity evaluation and audit (posted at ksuswine.org) performed during each visit. Each mill offered its own biosecurity challenges, either with the normal operating procedures or required tasks to be performed within facility limitations.

在4天的时间里,总共采集了573个样本,其中381个样本来自饲料原料或成品饲料,其余的192个样本是来自4个设施的环境样本。

A total of 573 samples were taken over the course of four days, with 381 of those samples consisting of feed ingredient or finished feed, and the remaining 192 samples environmental swabs, collected across the 4 sites.

饲料原料和成品饲料样品使用一次性塑料容器收集。每个原料/饲料最初收集10个独立样本。散装存储的产品是在传送过程中多次随机采样,袋装产品是从现场的10个不同的袋子中各取样品。每个样本都被独立分装和保存,以供各自分析,并从分析的10个样本中做一个混合样本进行分析。

Feed ingredient and finished feed samples were collected using single-use plastic tubs. For each separate item, 10 individual samples were collected initially. For bulk-storage products, samples were either drop-collected or grabbed at multiple times while being conveyed. For bagged products, samples were obtained from each of 10 different bags onsite. Each sample was kept separate for individual analysis, with an additional blended composite sample created from the 10 samples analyzed.

环境样品的采集使用了两种不同的采样方法。饲料厂内易于用拭子采样的区域用纱布拭子采样,采样方法是:取10cm×10cm的棉质纱布方巾,用5毫升pH为7.2的磷酸盐缓冲液(PBS)中浸湿,然后对面积约20cm×20cm的区域进行采样。对于不易进入的区域,如料仓或卡车拖车的内部,利用滚动油漆刷采样10。采样的地点根据每个设施的不同而有所不同,但在3个饲料生产设施(饲料厂1-3)中所选的采样点是类似的。每个拭子分别采集4个区域中的一个,包括饲料或原料的直接接触表面(区域1),近距离(1米内)非接触表面(区域2),非近距离(距离1米以上)非接触表面(区域3),和瞬态表面,例如可移动的工具、人员和非饲料或原料运输工具(区域4)。来自第四个设施(扩繁场)的试子样本是根据与猪的距离划分区域的。包括直接的饲料接触表面(区域5),栏内地板、栏位分隔板、饲喂器、饮水器等在内的直接的猪接触表面(区域6),以及包括员工通道、工作区、饲料存储区和风机等在内的非猪接触面(区域7)。

For the environmental samples, two different collection methods were used. Cotton gauze swabs were utilized for areas within the mill that had easy access for swab collection. The gauze swabs were collected by swabbing a surface area of approximately 20cm × 20cm with a 10cm × 10cm cotton gauze square soaked in 5 ml of phosphate buffered saline (PBS) with a pH of 7.2. For areas without easy access, such as the interior of storage bins or truck trailers, a paint roller was utilized, as described by Dee et al., 2014.10 Locations did vary based on each individual site, but within the 3 feed manufacturing facilities (Sites 1-3), similar locations were chosen. Each swab was assigned one of four zones, including direct feed or ingredient contact surfaces (Zone 1), close proximity (within 1m) non-contact surfaces (Zone 2), non-contact surfaces without close proximity (>1 m of separation) (Zone 3), and transient surfaces, such as moveable tools, employees, and non-feed or ingredient delivery vehicles (Zone 4). Swabs taken from the fourth facility, the multiplier farm, were assigned zones based on proximity to pigs. This included direct feed-contact surfaces (Zone 5), direct pig-contact surfaces (Zone 6) including pen flooring, pen walls, feeders, and waterers (pig contact), and non-pig contact surfaces (Zone 7) including employee walkways, work areas, feed storage, and fans (non-pig contact).

样本制备与分析

Sample preparation and analysis

饲料和原料样本是分别单独采集的,对于每个产品,从每个独立样本中取约25克样本并混合产生一个复合样本。所有产品样本在运输前均在4oC下储存。棉纱环境拭子样本在采样前先用5毫升的PBS溶液在圆锥管中对方形棉质纱布进行浸泡。采样后,再加入20毫升的PBS溶液。试子样本在运输前在4oC下储存。用滚动油漆刷采集的样本在采样后立即放在塑料自封袋中保存,每个油漆刷中加入200毫升pH为7.2的PBS溶液(以便运输),搅动,然后静置一小时。

Feed and ingredient samples were collected individual. For each product, a composite sample was created by dividing and blending approximately 25 g from each individual sample. All product samples were stored at 4˚C until shipped. Cotton gauze environmental swabs submitted for testing were initially prepared by adding 5 mL of PBS to a cotton gauze square in a conical tube prior to collection. After samples were collected, 20 ml of additional PBS were added. Swabs were kept at 4° C until shipped. The paint rollers used for sample collection were placed into large zipper-seal plastic bags immediately after use. To prepare them for shipment, 200 ml of 7.2 pH PBS was added to each roller. The sample was then agitated and allowed to set for 1 hour.

从每个样品中取出10毫升PBS溶液,在运输前在4oC下储存。取样后,样本用干冰保存并运送至爱荷华州兽医诊断实验室。样品在麦康凯琼脂上培养,然后鉴定每个样品中生长最多的三种细菌,并通过指定生长指数值进行报告。

10 mL of the PBS was removed from each sample and stored at 4˚C until shipped. After collection, samples were store and shipped on dry ice to the Iowa State Veterinary Diagnostic Laboratory. Samples were cultured on MacConkey agar, and the three types of bacteria with largest growth for each sample were identified and reported by assigning a growth index value.

统计分析

Statistical analysis

根据报告的生长情况,细菌生长结果的指标值分别为0、1、2、3或4。0表示阴性结果,1、2、3或4分别表示少量、低、中、高阳性结果。每个样品都有一个总体指数和,每个细菌都有一个生长指数值。用SAS GLIMMIX 程序(Version 9.4, SAS Institute Inc., Cary, NC)对数据进行分析,并用Tukey-Kramer法进行校正。

Bacterial growth results were assigned an index value of either 0, 1, 2, 3, or 4 based on reported growth, with 0 representing a negative result and values 1, 2, 3, or 4 a few, low, moderate, or high positive result, respectively. Growth values were reported as individual bacteria, with each sample receiving an overall index sum. The data were analyzed using the GLIMMIX procedure of SAS (Version 9.4, SAS Institute Inc., Cary, NC) with the Tukey-Kramer adjustment using the assigned location zones as the levels with the response variables of total growth (sum of index values) and presence of bacteria typical used to indicate fecal matter is present (fecal indicators).

结果和讨论 Results and discussion<<

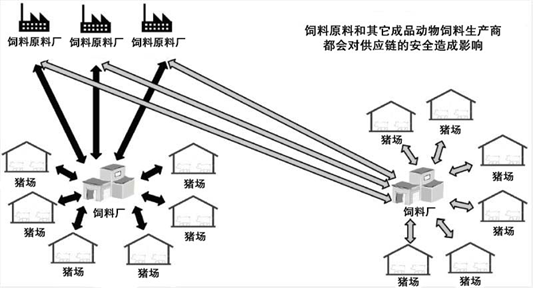

美国饲料行业不适合这些类型的清洗和消毒过程,因此必须将主要重点放在防止致病性病毒进入饲料厂,特别是因为饲料厂是多个猪场之间的交通交叉枢纽。图1显示了饲料厂的正常交通流情况。根据饲料厂规模的不同,有的饲料厂一天会接收几十辆饲料原料运输车。饲料厂把这些原料进行混合,然后运送到几十个农场。养猪业和养禽业已经开发了高效的生物安全程序,以防止人员或运输车辆成为病毒的传播媒介。这些程序包括换鞋子、衣服和/或淋浴,以及针对运输工具的动态生物安全金字塔的规定。许多现代养猪生产体系实施了类似于BSL2或BSL3实验室的生物安全防护措施,但实施规模要大得多。然而,这些措施尚未在饲料厂、人员车辆以及饲料卡车上实施。

The US feed industry is not designed for these types of cleaning and disinfection processes, so the primary focus must be on keeping pathogenic viruses out of feed mills, particularly because feed mills are a central point of cross-traffic among multiple farms or sites. Figure 1 demonstrates just a snapshot of the normal traffic flow of feed mills. Depending on mill size, it can receive dozens of ingredient delivery vehicles daily. The mill mixes ingredients together and distributes them to dozens of farms. The swine and poultry industries have developed highly effective biosecurity procedures that prevent people or transport vehicles from serving as fomites for viral. These include protocols for changing shoes, clothing, and/or showering and dynamic biosecurity pyramids for transport vehicles. Many modern swine production systems implement biocontainment practices similar to BSL2 or 3 laboratories but on a much larger scale. However, these same procedures have not been implemented at feed mills and with personnel or feed trucks.

图1:虽然生物安全已经发展到可以防止农场之间的接触,但由于饲料的运送,农场之间仍然存在频繁的交通路径交叉。

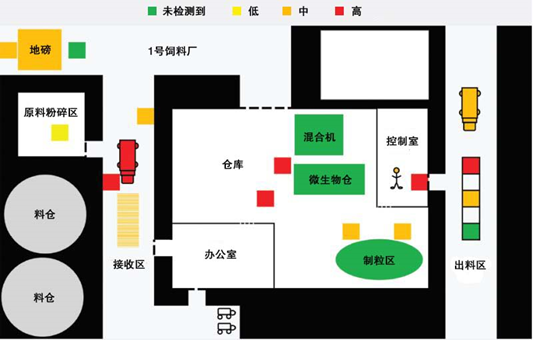

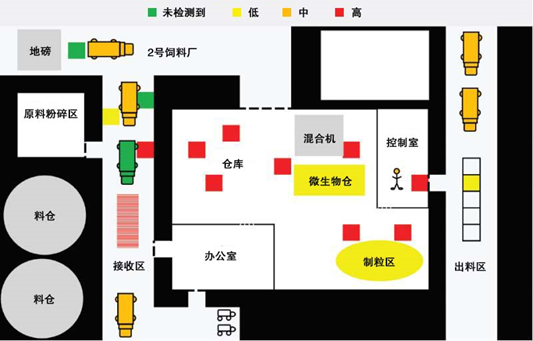

每个饲料厂的扩张床吸附层析法(EBAC)结果如图2、3和4所示。饲料厂1,2和3的审计分数分别为83%、67%和42%。1号饲料厂外门上锁,要求员工在进入前要换衣服和鞋子,并在门内设置洗手处。地磅在围墙内,会偶尔用于称公司自己的猪。在本厂,可检测的EBAC的饲料接触表面只有地磅、原料接收坑、成品饲料仓和成品饲料卡车。2号饲料厂的外门没有上锁,也没有使用洗手池(除了卫生间外),但员工在进入前需要换衣服和鞋子。本厂也没有围墙,地磅常用来称猪。所有检测的饲料接触表面都发现了中度水平的EBAC,其中饲料加工区的地板上EBAC水平更高。3号饲料厂的外门没有上锁,也没有使用洗手池(除了卫生间外),但员工在进入前需要换衣服和鞋子。本厂也没有围墙,地磅常用来称公司自己的猪和区域内其他猪场的猪。本厂的饲料接触面较难取样,但是所取得的样本中经检测EBAC水平都很高。

Maps of EBAC levels per facility are shown in Figures 2, 3, and 4. Audit scores for each facility were 83%, 67%, and 42% for Site 1, 2, and 3, respectively. Site 1 utilized locked exterior doors, required employees to change clothes and shoes prior to entry, and had handwashing stations located inside the doorway. The scale was located within a fenced perimeter, and was used to weigh company-owned pigs occasionally. In Site 1, the scale, receiving pit, finished feed bin, and finished feed truck were the only feed-contact surfaces with detected EBAC. At Site 2, exterior doors were not locked and handwashing stations not used except for restroom purposes, but employees changed clothes and shoes prior to entry. There was no perimeter fence and the scale was routinely used to weigh animals. There was a moderate quantity of EBAC detected in all feed contact surfaces tested, with high levels on the floor of the manufacturing area. At Site 3, exterior doors were not locked and handwashing stations not used except for restroom purposes, but employees changed clothes and shoes prior to entry. There was no perimeter fence and the scale was routinely used to weigh company-owned animals, as well as those from other within the region. While it was difficult to obtain samples from feed contact surfaces in Site 3, those collected all had high levels of EBAC.

图2:1号饲料厂的卫生情况。生物安全相对很不错。

图3:2号饲料厂的卫生情况。生物安全中等至较弱。

图4:3号饲料厂的卫生情况。生物安全很弱。

在所有设施中,2区、3区、4区、6区和7区报告的平均细菌生长指数值相似(P≤0.05),2区和3区的平均指数为18.1,7区的平均指数为21.4。1区、2区、3区、4区和6区的平均生长指数值相近(P≤0.05)。各样品组中,5区的生长指数为倒数第二(P > 0.05),其中生长指数最低的组为原料和成品饲料样品。研究发现,各区的情况与该区域是否存在EBAC之间存在中度相关性(r = 0.463, P≤0.0001),但没有证据表明各区情况与是否存在粪便指示菌之间存在相关性(r = 0.028, P > 0.05)。有明显的证据表明EBAC的存在与各饲料厂自身情况之间存在微弱的相关性(r = 0.201, P≤0.0001)。

Across all facilities, zones 2, 3, 4, 6, and 7 had the similar reported mean growth values (P ≤ 0.05) assigned, ranging from a mean index score of 18.1 for zones 2 and 3 to a mean index value of 21.4 for zone 7. Zones 1, 2, 3, 4, and 6 had similar mean growth values (P ≤ 0.05). Zone 5 had the second-to-lowest demonstrated growth of all sample groups (P > 0.05), with the group of samples with the lowest growth index value being the raw ingredient and finished feed samples. There was evidence of moderate correlation noted (r = 0.463, P ≤ 0.0001) between the zone and presence of EBAC, but no evidence of correlation (r = 0.028, P > 0.05) between zone and presence of fecal indicator bacteria. There was significant evidence of a weak correlation (r = 0.201, P ≤ 0.0001) between EBAC presence and site.

显然,遵守生物安全规定对肠杆菌科细菌在整个饲料厂的流行和分布有重要影响。随着各设施开始将生物安全从猪场转移到饲料厂,使用环境监测来评估生物安全漏洞的风险以及成功地缓解这些风险将是非常有用并且必要的。

Clearly, compliance with biosecurity protocols had a substantial impact of Enterobacteriaceae prevalence and distribution throughout the feed mill. As facilities begin to transition biosecurity from the farm to the feed mill, using environmental monitoring to evaluate risk for biosecurity gaps, as well as success in their mitigation, will be useful and necessary.

服务热线:400-808-6188

Copyright©2010-2022 https://www.zhuwang.cc